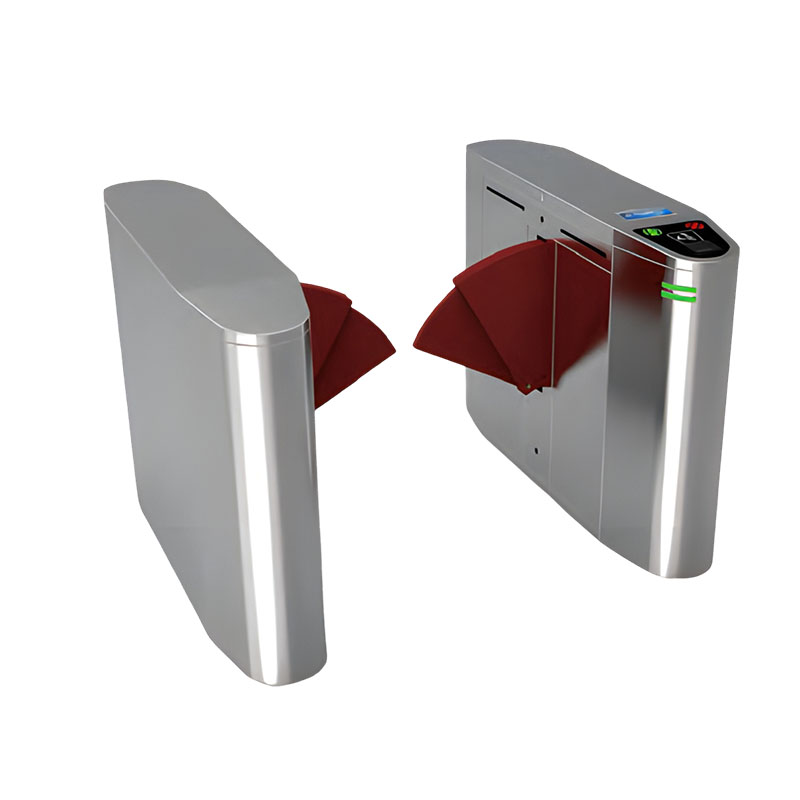

Design and durability study of mechanical transmission system of pedestrian access gate

Release Time : 2024-12-30

The mechanical transmission system of the pedestrian access gate is one of its core components, and its design is directly related to the performance and durability of the equipment. First of all, in terms of motor selection, a motor with appropriate power and torque should be selected according to the load requirements and operating frequency of the channel gate. For example, for gates that are frequently opened and closed, a high-efficiency, high-torque brushless DC motor can provide stable power output, reduce failures caused by motor overload or overheating, extend service life, and ensure the rapid response and smooth operation of the gate.

In terms of transmission structure, common ones are belt drive, chain drive and gear drive. Belt drive has good shock absorption and buffering performance and can reduce noise, but the tension needs to be checked regularly and the belt needs to be replaced to prevent slippage and wear; chain drive is suitable for larger loads and long-distance transmission. Its structure is sturdy, but it needs lubrication and maintenance to reduce wear and elongation; gear transmission has high precision, high transmission efficiency and durability, but the design and manufacturing process requirements are high, and the meshing accuracy and material strength of the gears need to be ensured to prevent tooth surface wear and fatigue fracture. Reasonable selection of transmission mode and optimization design according to actual working conditions can improve transmission efficiency and reliability.

For key transmission shafts and connectors, high-strength, wear-resistant metal materials such as stainless steel or alloy steel should be selected, and appropriate heat treatment processes should be carried out to improve their surface hardness and wear resistance. At the same time, the structural design of the shaft should be optimized to avoid stress concentration, and the weight should be reduced by increasing the fillet radius and using hollow shafts, so as to improve the bending and torsion resistance of the shaft and ensure that it will not deform or be damaged during long-term operation.

In the protection design of mechanical transmission systems, it is very important to install protective covers. The protective cover can effectively block dust, moisture and debris from entering the transmission parts, prevent wear, corrosion and jamming of parts caused by foreign matter intrusion, keep the transmission system clean and smooth, significantly improve its durability, reduce maintenance costs and downtime, ensure that the pedestrian access gate can work stably and reliably in various complex environments, meet the long-term needs of personnel traffic management in public places, and improve the overall performance and use value of the equipment.